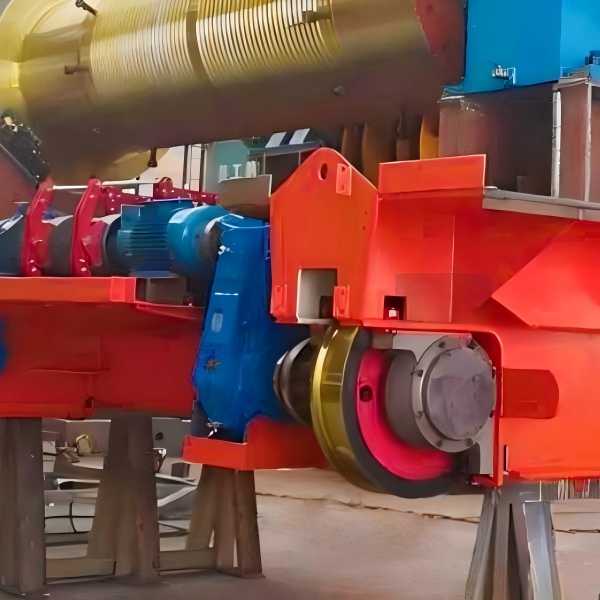

Step-by-Step Guide to Crane Wheel Installation

Proper crane wheel installation is essential to ensure smooth crane operation, prevent premature wear, and guarantee safety in lifting applications. In this guide, we’ll show you how to install a crane wheel step by step, following industry-proven methods.

If you are looking for replacement parts or OEM-quality crane wheels, visit our Crane Wheels Product Page for detailed specifications and drawings.

1. Preparation and Safety

Before starting, always disconnect power and apply proper lockout/tagout procedures. Use certified lifting and blocking devices to support the bridge or trolley.

Verify that the replacement wheel matches the original in diameter, flange, and bore size. You can find detailed wheel specifications on the HNHL Crane Accessories Page.

For general crane safety regulations, refer to OSHA’s Crane Safety Standards.

2. Gather Tools and Materials

Prepare the following: hydraulic jack or hoist, torque wrench, bearing puller, dial indicator, feeler gauge, and anti-seize compound.

Always use original bearings and seals recommended by the manufacturer to ensure alignment accuracy and longer service life.

3. Remove the Old Wheel

Support the bridge securely and remove wheel guards. Unbolt the wheel assembly carefully to avoid damaging the axle or hub.

If the wheel is seized, use a puller or hydraulic press — never hammer directly on the wheel or bearing.

4. Inspect Axle and Bearings

Clean the axle, keyway, and hub. Check for wear, corrosion, or misalignment. Replace bearings if clearance exceeds specifications.

5. Fit the New Wheel

Apply a thin coat of anti-seize compound to the axle before fitting the new wheel.

Install new bearings using a press and make sure seals and covers are positioned correctly. This step ensures smooth rotation and prevents oil leakage.

6. Alignment and Fastening

Slide the wheel onto the axle and align keyways. Use a dial indicator to check for flange runout and lateral clearance.

Tighten all fasteners using a torque wrench according to manufacturer specifications.

For a detailed explanation of alignment tolerances, refer to ISO 12488 Crane Runway and Wheel Alignment Standards.

7. Functional Testing

Rotate the wheel manually or jog the crane slowly. Check for vibration, noise, or heat.

During the first 30 minutes of operation, verify that the wheel and bearings are seated properly and that the travel path is even.

8. Final Checks and Maintenance

After installation, recheck torque values and record wheel serial numbers in your maintenance log.

Regular inspections — such as monthly visual checks and quarterly lubrication — will extend the wheel’s lifespan.

Troubleshooting Tips

-

Uneven wear: Recheck rail and wheel alignment.

-

Abnormal noise: Check bearings and lubrication.

-

Overheating: Inspect brake adjustment and wheel clearance.

For a complete list of crane wheel types and materials, visit HNHL Crane Wheels.

HNHL Crane provides high-quality crane wheels, bearings, end carriages以及 custom maintenance solutions for various overhead crane systems.

Visit our homepage at www.hnhlcrane.com to learn more about our lifting equipment solutions.

Frequently Asked Questions (FAQ) about Crane Wheel Installation

1. What are the main steps to install a crane wheel correctly?

The main steps include inspecting the crane wheel and rail, preparing the installation tools, aligning the wheel set accurately, tightening the bolts according to the torque requirements, and conducting a test run. Following these steps ensures stable operation and reduces wear.

2. How do I know when a crane wheel needs to be replaced?

If you notice irregular noise, uneven wear on the wheel tread, or deviation in crane movement, it’s time to check the wheel. In severe cases, cracks or flaking may appear — in such situations, replacement is necessary.

3. What tools are required for crane wheel installation?

Common tools include torque wrenches, hydraulic jacks, feeler gauges, alignment lasers, and lubricants. Using proper tools ensures precision and safety during installation.

4. Can I install new crane wheels without removing the entire end carriage?

In some cases, yes — particularly when using split-type end carriages. However, for major maintenance or precise alignment, it’s recommended to remove the end carriage for complete inspection.

5. How often should I inspect the crane wheels after installation?

We recommend performing a basic inspection every 3 months, including checking the wheel alignment, bearing condition, and bolt tightness. Regular maintenance ensures long-term reliability and safety.