Boben z žično vrvjo

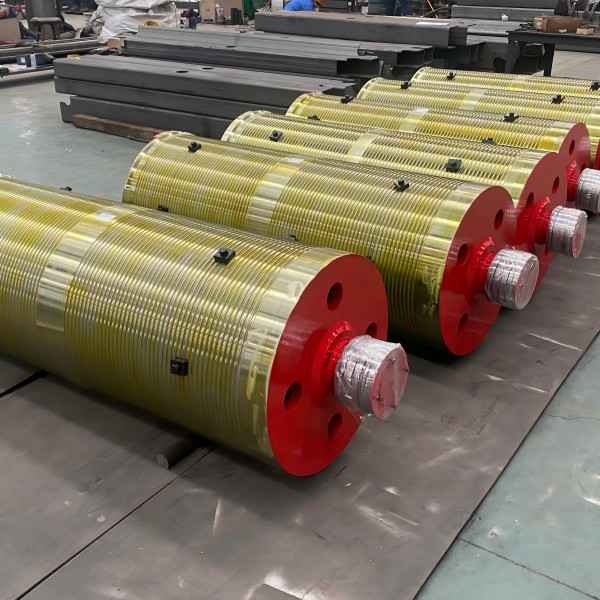

Specifikacije bobna z žično vrvjo:

-

Premer × dolžina: Φ300×1000, Φ400×1500, Φ500×1500, Φ650×2000, Φ800×2000, Φ800×3600, Φ1000×3600

-

Material bobna: Q235B, Q345B

-

Vrsta priključka bobna: WZL spojka bobna

-

Postopek izdelave bobna: Jeklena plošča, valjanje, brezšivne jeklene cevi

-

Velikost utora bobna: Premer žične vrvi: določen s premerom žične vrvi

-

Naročila po meri: Velikost po meri je na voljo na podlagi vaših predloženih risb.

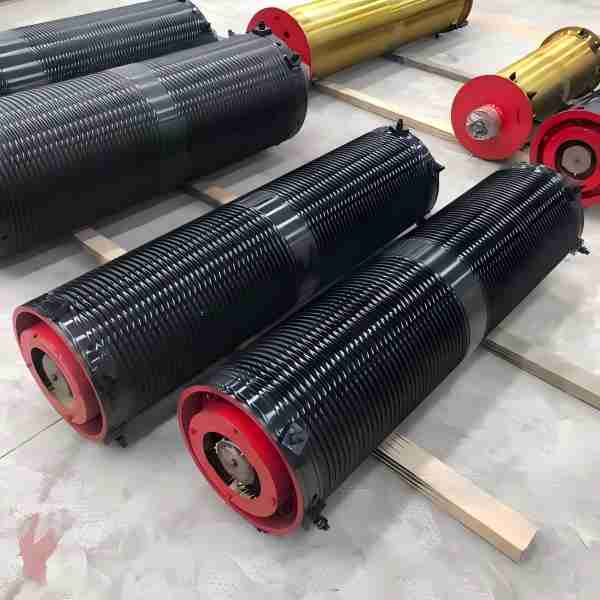

Uvod v boben z žično vrvjo

-

Funkcija bobna z žično vrvjo

Boben z žično vrvjo ima ključno vlogo pri dvižnih strojih. Pomaga pri upravljanju žične vrvi in zagotavlja nemoteno delovanje dvižnega sistema. -

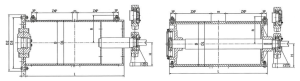

Struktura bobna z žično vrvjo

Sestav bobna je sestavljen iz več sestavnih delov: bobna, gredi bobna, sklopke zobniške plošče (ali velikega zobnika), pesta bobna, telesa ležaja in ležajev. Vsak del prispeva k splošni funkcionalnosti in učinkovitosti bobna. -

Materiali, uporabljeni za izdelavo bobna

Proizvajalci za izdelavo bobna običajno uporabljajo varjene jeklene plošče Q235B ali Q345B ali brezšivne jeklene cevi. Ti materiali zagotavljajo vzdržljivost in trdnost pri velikih obremenitvah.

Proizvodni proces Boben žerjava

Proizvodni postopek vključuje naslednje korake:

-

Rezanje materiala: Začnite z rezanjem jeklenih plošč Q235B ali Q345B na zahtevane dimenzije.

-

Valjanje telesa bobna: Karoserija je valjana in varjena, pri čemer se oblikujejo vzdolžni šivi za strukturno celovitost.

-

Inšpekcijski pregled: Preglejte vzdolžne zvare in preverite geometrijske mere, vključno s premerom, dolžino in toleranco ovalnosti notranjega premera. Pri bobnih z večjim premerom ojačajte z dodatnimi rebri v skladu s procesnimi specifikacijami.

-

Strojna obdelava: Obdelujte telo bobna in ustvarite obročaste utore. Pri bobnih, pri katerih je potrebna groba obdelava zunanjega kroga, obdelajte tudi zunanji krog.

-

Varjenje telesa: Z varjenjem obodnih šivov podaljšajte ohišje bobna.

-

Varjenje ojačitev: Po potrebi dodajte ojačitvena rebra na konce bobna. Zvarite in preverite obodne šive in dodatke za strojno obdelavo v skladu s procesnimi zahtevami.

-

Končna obdelava: Postopek strojne obdelave zaključite z rezanjem bobna na določeno dolžino in oblikovanjem koncev z zapornimi utori ali poševnicami.

-

Varjenje: Prirobnično ploščo, gred in notranje podporne obroče privarite na konce bobna.

Previdnostni ukrepi

Pri delu z žerjavi, ki imajo večjo dvižno višino, uporaba površine z vodilnim spiralnim žlebom ali gladkega bobna omogoča večplastno navijanje, kar pomaga zmanjšati velikost bobna. Vendar lahko ta metoda povzroči hitrejšo obrabo žične vrvi, zato je primerna za žerjave z nizko hitrostjo in manjšo tonažo.

Pri visokozmogljivih dvižnih strojih in žerjavih z veliko tonažo so sklopi bobnov iz jeklene pločevine zaradi svoje robustnosti in zanesljivosti običajno najprimernejša možnost.

Zamenjava žične vrvi v sestavu bobna

Če želite zamenjati žično vrv v bobnu, najprej sprostite ploščo za vpenjanje jeklene vrvi na enem koncu bobna. S tem dejanjem se en konec vrvi spusti na tla. Nato novi konec žične vrvi povežite s starim in zagotovite, da bo spoj med namestitvijo gladko prešel skozi režo jermenice.

Parametri in izbira bobna za žične vrvi:

Tip bobna WZL Tip bobna C

| D×L | Risba št. | Spojka bobna | Zmogljivost dvigovanja (t) |

Višina dviga (m) | D1 | D2 | D3 | m | P | R | S | H | Reduktor |

| Φ400×1000 | TW1022A | WZL05 | 5 | 15 | 409 | 510 | 460 | 48 | 16 | 248 | 16 | 210 | QJYD3-225 |

| TW1028A | QJS-D280 | ||||||||||||

| Φ400×1500 | TW1023A | WZL05 | 5/10 | 22/16 | 409 | 510 | 460 | 150/50 | 16 | 248 | 16 | 210 | QJYD3-225 |

| TW1029A | QJS-D280 | ||||||||||||

| φ500×1500 | TW1024A | WZL06 | 16/20 | 16/12 | 512 | 640 | 580 | 120 | 20 | 316 | 20 | 260 | QJYD3-280 |

| TW1030A | WZL07 | QJRS-D400 | |||||||||||

| φ650×2000 | TW1025A | WZL09 | 32 | 17 | 664 | 810 | 750 | 150 | 24 | 402 | 24 | 360 | QJYD3-400 |

| TW1031A | QJRS-D500 | ||||||||||||

| φ800×2000 | TW1027A | WZL10 | 50 | 12 | 816 | 960 | 900 | 350 | 28 | 478 | 26 | 420 | QJYD3-450 |

| TW1032A | QJRS-D560 | ||||||||||||

| φ800×3600 | TW505A | WZL11 | 75 | 20 | 816 | 950 | 890 | 450 | 34 | 498 | 30 | 420 | QJYD3-500 |

| TW1033A | QJRS-D630 | ||||||||||||

| φ1000×3500 | TW632A | WZL12 | 100/125 | 20 | 1020 | 1200 | 1100 | 300 | 36 | 595 | 34 | 530 | QJYD3-560 |

| TW1034A | QJRS-D710 |

Videoposnetek

Vprašanja in odgovori

1. Kaj je boben z žično vrvjo in kako deluje?

Boben žične vrvi je valjast sestavni del, ki se uporablja v žerjavih, dvigalih in vitlih za shranjevanje in vodenje žične vrvi med dvigovanjem. Zagotavlja nemoteno navijanje in odvijanje vrvi. Za zanesljive rešitve za bobne obiščite www.hnhlcrane.com.

2. Iz katerih materialov so izdelani bobni za žične vrvi?

Bobni z žično vrvjo so običajno izdelani iz Jeklene plošče Q235B ali Q345B, valjane in varjene v obliko. Lahko so izdelani tudi iz brezšivne jeklene cevi ali drugih posebnih materialov, odvisno od delovnih pogojev. Več informacij na www.hnhlcrane.com.

3. Katere vrste bobnov za žične vrvi so na voljo?

Glavne vrste so gladki bobni, vrezani bobni in deljeni bobni. Bobni z žlebovi zmanjšajo obrabo vrvi in izboljšajo natančnost navijanja. Raziščite različne možnosti na www.hnhlcrane.com.

4. Kako izbrati pravi boben žične vrvi za moj žerjav?

Izbira je odvisna od dvižne zmogljivosti, premera vrvi, trdnosti materiala in delovnega okolja. Bobni iz jeklene plošče Q345B so pogosto izbrani za žerjave za velike obremenitve, medtem ko so brezšivni cevni bobni primernejši za kompaktne in visoko trdnostne aplikacije. Strokovno svetovanje je na voljo na www.hnhlcrane.com.

5. Kako pogosto je treba pregledovati bobne z žično vrvjo?

Pri rednih pregledih je treba preveriti obrabo utorov, površinske razpoke ali deformacije.. Pogostost pregledov mora ustrezati delovnemu razredu in intenzivnosti uporabe žerjava. Nasveti za vzdrževanje so na voljo na www.hnhlcrane.com.

6. Ali lahko bobne z žično vrvjo prilagodim za posebne načine dvigovanja?

Da. Bobne lahko prilagodite v premer, dolžina, tip utora in material (kot so Q235B, Q345B ali brezšivne cevi), ki ustrezajo različnim sistemom žerjavov. Storitev OEM in ODM je na voljo na www.hnhlcrane.com.