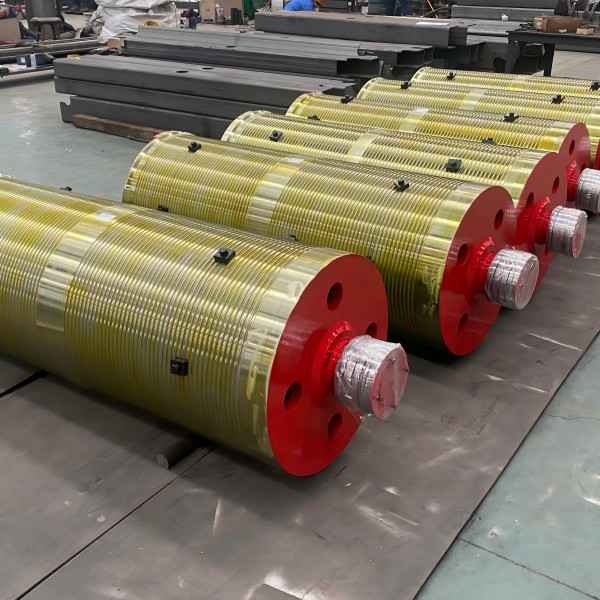

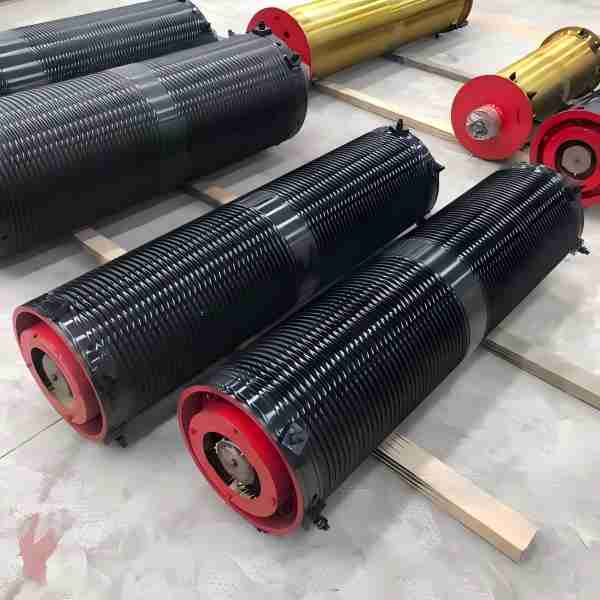

Wire Rope Drum

Wire Rope Drum Specifications:

-

Diameter × Length: Φ300×1000, Φ400×1500, Φ500×1500, Φ650×2000, Φ800×2000, Φ800×3600, Φ1000×3600

-

Drum Material: Q235B, Q345B

-

Drum Connection Type: C-type gear plate, WZL drum coupling

-

Drum Manufacturing Process: Steel plate rolling, seamless steel pipe

-

Drum Groove Size: Determined by the diameter of the wire rope

-

Custom Orders: Custom sizes available based on your provided drawings

Introduction to Wire Rope Drum

-

Function of the Wire Rope Drum

The Wire Rope Drum plays a crucial role in lifting machinery. It helps manage the wire rope and ensures smooth operation of the lifting system. -

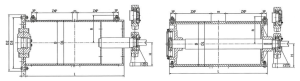

Structure of the Wire Rope Drum

The drum assembly consists of several components: the drum, drum shaft, gear plate coupler (or large gear), drum hub, bearing body, and bearings. Each part contributes to the overall functionality and efficiency of the drum. -

Materials Used for Manufacturing the Drum

Manufacturers typically use welded Q235B or Q345B steel plates, or seamless steel pipes to produce the drum. These materials ensure durability and strength under heavy load conditions.

Manufacturing Process of the Crane Drum

The manufacturing process involves the following steps:

-

Material Cutting: Begin by cutting Q235B or Q345B steel plates to the required dimensions.

-

Rolling the Drum Body: The body is rolled and welded, forming longitudinal seams for structural integrity.

-

Inspection: Inspect the longitudinal weld seams and check geometric dimensions, including diameter, length, and inner diameter ovality tolerance. For larger diameter drums, reinforce with additional ribs as per process specifications.

-

Machining: Machine the drum body, creating ring-shaped grooves. For drums requiring rough machining of the outer circle, process the outer circle as well.

-

Welding the Body: Extend the drum body by welding the circumferential seams.

-

Reinforcement Welding: If necessary, add reinforcement ribs to the ends of the drum. Weld and inspect the circumferential seams and machining allowances as per process requirements.

-

Final Machining: Finalize the machining process by cutting the drum to the specified length and shaping the ends with stop grooves or bevels.

-

Welding: Weld the flange plate, shaft, and inner supporting rings to the ends of the drum.

Precautions

When working with cranes that have a larger lifting height, using a surface with a guide spiral groove or a smooth drum allows for multi-layer winding, helping to reduce the drum’s size. However, this method may cause faster wire rope wear, making it suitable for slow-speed, light-duty cranes with lower tonnage.

For high-performance lifting machinery and large-tonnage cranes, steel plate drum assemblies are typically the preferred option due to their robustness and reliability.

Wire Rope Replacement in the Drum Assembly

To replace the wire rope in the drum assembly, first, loosen the steel rope clamping plate at one end of the drum. This action allows one end of the rope to drop to the ground. Then, connect the new wire rope end to the old one to ensure the joint smoothly passes through the pulley slot during installation.

Wire Rope Drum Parameters and Selection:

WZL type drum C type drum

| D×L | Drawing No. | Drum coupling | Lifting capacity (t) |

Lifting height (m) | D1 | D2 | D3 | m | P | R | S | H | Reducer |

| Φ400×1000 | TW1022A | WZL05 | 5 | 15 | 409 | 510 | 460 | 48 | 16 | 248 | 16 | 210 | QJYD3-225 |

| TW1028A | QJS-D280 | ||||||||||||

| Φ400×1500 | TW1023A | WZL05 | 5/10 | 22/16 | 409 | 510 | 460 | 150/50 | 16 | 248 | 16 | 210 | QJYD3-225 |

| TW1029A | QJS-D280 | ||||||||||||

| φ500×1500 | TW1024A | WZL06 | 16/20 | 16/12 | 512 | 640 | 580 | 120 | 20 | 316 | 20 | 260 | QJYD3-280 |

| TW1030A | WZL07 | QJRS-D400 | |||||||||||

| φ650×2000 | TW1025A | WZL09 | 32 | 17 | 664 | 810 | 750 | 150 | 24 | 402 | 24 | 360 | QJYD3-400 |

| TW1031A | QJRS-D500 | ||||||||||||

| φ800×2000 | TW1027A | WZL10 | 50 | 12 | 816 | 960 | 900 | 350 | 28 | 478 | 26 | 420 | QJYD3-450 |

| TW1032A | QJRS-D560 | ||||||||||||

| φ800×3600 | TW505A | WZL11 | 75 | 20 | 816 | 950 | 890 | 450 | 34 | 498 | 30 | 420 | QJYD3-500 |

| TW1033A | QJRS-D630 | ||||||||||||

| φ1000×3500 | TW632A | WZL12 | 100/125 | 20 | 1020 | 1200 | 1100 | 300 | 36 | 595 | 34 | 530 | QJYD3-560 |

| TW1034A | QJRS-D710 |

Video

Faq

1. What is a wire rope drum and how does it work?

A wire rope drum is a cylindrical component used in cranes, hoists, and winches to store and guide the wire rope during lifting operations. It ensures smooth winding and unwinding of the rope. For reliable drum solutions, visit www.hnhlcrane.com.

2. What materials are wire rope drums made of?

Wire rope drums are typically manufactured from Q235B or Q345B steel plates rolled and welded into shape. They can also be made from seamless steel pipes or other special materials depending on the working conditions. Learn more at www.hnhlcrane.com.

3. What are the types of wire rope drums available?

The main types include smooth drums, grooved drums, and split drums. Grooved drums reduce rope wear and improve winding accuracy. You can explore the different options at www.hnhlcrane.com.

4. How to choose the right wire rope drum for my crane?

Selection depends on lifting capacity, rope diameter, material strength, and operating environment. Q345B steel plate drums are often chosen for heavy-duty cranes, while seamless pipe drums are preferred for compact and high-strength applications. Professional guidance is available at www.hnhlcrane.com.

5. How often should wire rope drums be inspected?

Regular inspections are necessary to check for groove wear, surface cracks, or deformation. The inspection frequency should match the crane’s duty class and usage intensity. Maintenance advice can be found at www.hnhlcrane.com.

6. Can I customize wire rope drums for special lifting applications?

Yes. Drums can be customized in diameter, length, groove type, and material (such as Q235B, Q345B, or seamless pipe) to match different crane systems. OEM & ODM service is available at www.hnhlcrane.com.