Overhead crane wheels

Overhead Crane Wheels Parameters:

- Specifications: Φ250, Φ350, Φ400, Φ500, Φ600, Φ700, Φ800

- Wheel Material: ZG430-640, 45 steel, 50SiMn, 65Mn, 42CrMo

- Wheel Type: Double flange, Single flange, No flange

- Wheel Groove Width: Determined according to track model

- Custom Orders: We can manufacture based on your drawings and dimensions provided.

Overhead Crane Wheels

Product Overview

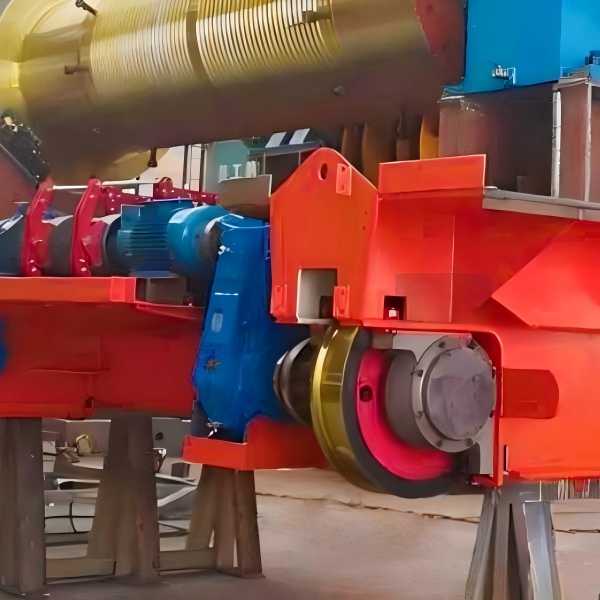

Overhead crane wheels play a crucial role in lifting equipment. They support heavy loads during movement and also provide the driving force for the entire system. Moreover, they offer high wear resistance, strong impact resistance, and accurate dimensional control. As a result, these wheels are widely used in gantry cranes, bridge cranes, port machinery, and mining equipment.

Material & Hardness

Manufacturers often choose 60#, 65Mn, or 42CrMo alloy steel to produce overhead crane wheels. In addition, the tread surface requires hardness levels between HRC40–48, while the core must maintain HBS187–229. To balance toughness and wear resistance, the hardened layer depth should remain ≥10mm. For example, container crane wheels made with optimized alloy steel and advanced heat treatment reach HRC55 on the tread, which increases service life by more than 50%.

Structure & Manufacturing Process

The production of overhead crane wheels involves forging, heat treatment, and precision machining. Instead of relying only on traditional forging, modern factories now apply die forging and high-frequency quenching. For instance, YFL-160KW quenching equipment combines CNC rotary heating with water spray cooling. Consequently, the hardening depth becomes more accurate, and wheel quality improves significantly.

Specifications & Applications

Wheel diameters range from Φ100mm to Φ1200mm. In addition, the tapered tread design enhances rail self-alignment during operation. According to the drive type, wheels are divided into driving wheels, which transmit power, and driven wheels, which mainly bear load transfer. Therefore, customers can select the right configuration based on crane type and working conditions.

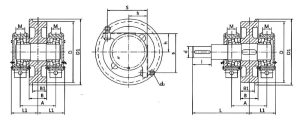

Single-Rim Wheelset

| Wheel diameter | Drawing No. | Size (mm) | ||||||||||||

| D | D1 | B | B1 | A | L | L1 | h | S | M | d | I | d1 | ||

| Φ250 | L754 | 250 | 280 | 90 | 70 | 180 | 237 | 130 | 80 | 180 | 30 | 45 | 82 | M20 |

| L755 | 250 | 280 | 90 | 70 | 180 | / | 130 | 80 | 180 | 30 | / | / | ||

| φ315 | L774 | 315 | 345 | 100 | 81 | 200 | 320 | 150 | 105 | 225 | 50 | 65 | 105 | |

| L775 | 315 | 345 | 100 | 81 | 200 | / | 150 | 105 | 225 | 50 | / | / | ||

| Φ350 | L756 | 350 | 380 | 100 | 81 | 200 | 320 | 150 | 105 | 225 | 50 | 65 | 105 | |

| L757 | 350 | 380 | 100 | 81 | 200 | / | 150 | 150 | 225 | 50 | / | / | ||

| φ400 | L758 | 400 | 440 | 120 | 100 | 240 | 365 | 170 | 120 | 260 | 50 | 80 | 130 | |

| L759 | .400 | 440 | 120 | 100 | 240 | / | 170 | 120 | 260 | 50 | / | / | ||

| Φ500 | L762 | 500 | 540 | 130 | 110 | 270 | 365 | 195 | 140 | 300 | 50 | 80 | 130 | |

| L763 | 500 | 540 | 130 | 110 | 270 | / | 195 | 140 | 300 | 50 | / | / | ||

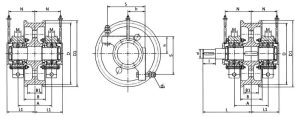

Double-Rim Wheelset

| Wheel diameter | Drawing No. | Size (mm) | ||||||||||||

| D | D1 | A | B | B1 | L | L1 | h | S | M | d | I | d1 | ||

| φ500 | L764 | 500 | 540 | 280 | 210/160 | 150/100 | 400 | 230 | 140 | 310 | 50 | 75 | 105 | M24 |

| L765 | 500 | 540 | 280 | / | 230 | 140 | 310 | 50 | / | / | ||||

| Φ600 | L766 | 600 | 640 | 280 | 210/160 | 150/100 | 415 | 230 | 140 | 310 | 50 | 85 | 130 | |

| L767 | 600 | 640 | 280 | / | 230 | 140 | 310 | 50 | / | / | ||||

| φ700 | L768 | 700 | 750 | 315 | 210/160 | 150/100 | 455 | 260 | 160 | 350 | 80 | 90 | 130 | M30 |

| L769 | 700 | 750 | 315 | / | 260 | 160 | 350 | 80 | / | / | ||||

| φ700 | L770 | 800 | 850 | 365 | 210/160 | 150/100 | 500 | 300 | 190 | 410 | 90 | 95 | 130 | |

| L771 | 800 | 850 | 365 | / | 300 | 190 | 410 | 90 | / | / | ||||

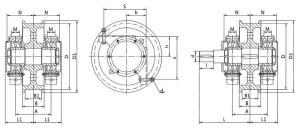

Heavy-Duty Wheelset

| Wheel diameter | Drawing No. | Size (mm) | ||||||||||||

| D | D1 | B | B1 | A | L | L1 | h | S | M | d | I | d1 | ||

| Φ600 | L174B | 600 | 650 | 210/160 | 150/100 | 325

325 |

470 | 255 | 180 | 390 | 70 | 95 | 130 | M24 |

| L175B | 600 | 650 | / | 255 | 180 | 390 | 70 | / | / | |||||

| φ700 | L176B | 700 | 750 | 210/160 | 150/100 | 360

360 |

500 | 280 | 200 | 440 | 80 | 110 | 165 | M30 |

| L177B | 700 | 750 | / | 280 | 200 | 440 | 80 | / | / | |||||

| Φ700 | L178B | 700 | 750 | 210/160 | 150/100 | 380

380 |

500 | 305 | 220 | 485 | 80 | 110 | 165 | |

| L179B | 700 | 750 | / | 305 | 220 | 485 | 80 | / | / | |||||

| φ800 | L196B | 800 | 850 | 210/160 | 150/100 | 380

380 |

500 | 305 | 220 | 485 | 80 | 110 | 165 | |

| L197B | 800 | 850 | / | 305 | 220 | 485 | 80 | / | / | |||||

Video

Faq

Q1: What are overhead crane wheels and why are they important?

A1: Overhead crane wheels are key parts that support loads and enable the crane to travel smoothly on rails. HLCRANE provides high-quality wheels designed for reliable performance. More details at www.hnhlcrane.com.

Q2: What materials are used for overhead crane wheels?

A2: Common materials include 60#, 65Mn, and 42CrMo alloy steel. HLCRANE selects and processes these steels to ensure wear resistance and long service life. Visit www.hnhlcrane.com for specifications.

Q3: Can overhead crane wheels be customized?

A3: Yes, HLCRANE offers customized wheels with diameters ranging from Φ100mm to Φ1200mm. These wheels can be tailored for gantry cranes, bridge cranes, port equipment, and mining machinery. See options at www.hnhlcrane.com.

Q4: What are the advantages of forged overhead crane wheels?

A4: Forged wheels deliver higher hardness, longer lifespan, and excellent rail alignment. HLCRANE uses advanced heat treatment processes to improve performance. Learn more at www.hnhlcrane.com.

Q5: Are both driving and driven crane wheels available?

A5: Yes, HLCRANE supplies both driving wheels for power transmission and driven wheels for load support. This ensures a complete crane wheel solution. Check www.hnhlcrane.com for details.

Q6: Why choose a Chinese supplier for crane wheels?

A6: Working with HLCRANE gives you strict quality control, competitive pricing, and reliable global export services. Discover more at www.hnhlcrane.com.