Crane gear couplings

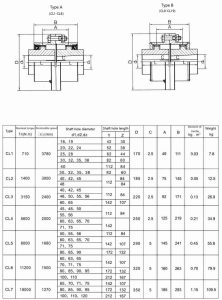

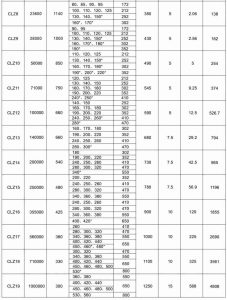

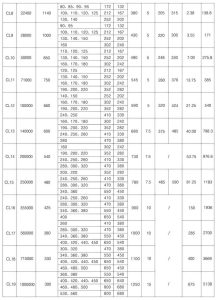

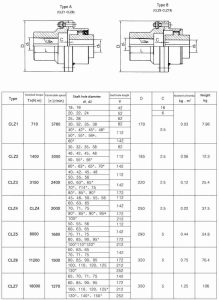

Crane Gear Couplings Parameters:

- Maximum Allowable Torque: 710 Nm to 1,000,000 Nm

- Maximum Speed: 7100 rpm to 700 rpm

- Coupling Material: ZG430-640, 45 steel

- Coupling Types: Full-tooth couplings and half-tooth couplings

- Custom Options: You can provide your own drawings, and we will manufacture according to the specified dimensions.

Crane gear couplings are essential mechanical components used to transmit torque, connect two coaxial or nearly parallel rotating shafts, and compensate for small angular and radial misalignments. Typically, they consist of two parts: the driving shaft and the driven shaft. Moreover, they are widely used in gear reducers to facilitate torque transmission. The design and application of crane gear couplings take into account several factors to ensure their performance and reliability, including but not limited to:

- Compensatory Flexibility: They can adjust for relative displacement between the rotating components, providing compensation for manufacturing and installation errors, temperature variations during operation, and deformations under load.

- Shock Absorption: For situations with frequent load starting or changing operational loads, the coupling should incorporate elastic elements that offer cushioning and vibration damping, thereby protecting both the prime mover and the working machine from potential damage.

- Safety and Reliability: They have sufficient strength and longevity to ensure safe operation under various working conditions.

- Simple Structure: They are easy to assemble, disassemble, and maintain, thus reducing both maintenance costs and time.

When selecting the type of coupling, one should consider the required torque transmission capacity and characteristics, as well as the need for shock absorption, vibration damping, and the potential for resonance. Crane gear couplings are used in fields such as metallurgy, mining, lifting and transportation, as well as in heavy machinery across industries like petroleum, chemical engineering, and general machinery. These couplings are known for their compact radial size, high load-bearing capacity, high transmission efficiency, low noise, and extended maintenance intervals, making them particularly suitable for low-speed, heavy-duty conditions.

Video

Faq

Q1: What is a crane gear coupling and how does it work?

A: A crane gear coupling is a mechanical device used to connect two shafts, transmitting torque while compensating for slight misalignment. It consists of two hubs with external gear teeth and a sleeve with internal teeth, ensuring reliable power transmission in crane applications.

Q2: What are the main advantages of using gear couplings in cranes?

A: Gear couplings provide high torque capacity, compact design, and excellent durability. They can accommodate angular, axial, and radial misalignments, making them ideal for heavy-duty lifting equipment such as overhead cranes, gantry cranes, and hoists.

Q3: What materials are commonly used for crane gear couplings?

A: Most crane gear couplings are manufactured from high-strength alloy steel with precision heat treatment. This ensures high load-bearing capacity, wear resistance, and long service life under demanding crane operations.

Q4: How do I select the right gear coupling for my crane?

A: Selection depends on torque requirements, shaft size, speed, misalignment tolerance, and working environment. Our engineering team at www.hnhlcrane.com can recommend the most suitable coupling based on your crane specifications.

Q5: What maintenance is required for crane gear couplings?

A: Regular inspection, lubrication, and alignment checks are essential. Proper lubrication reduces wear and ensures smooth operation. Worn-out seals or damaged gear teeth should be replaced promptly to avoid downtime.

Q6: Can crane gear couplings be customized?

A: Yes, we offer customized gear couplings in different sizes, torque ratings, and surface treatments according to customer requirements. For OEM or replacement parts, please contact us directly via www.hnhlcrane.com.