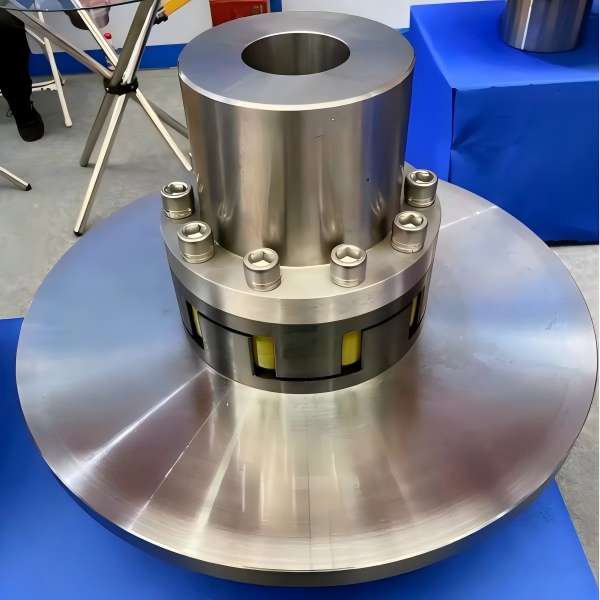

Brake Disc Jaw Elastic Coupling

MLPK Brake Disc Jaw Elastic Coupling Specifications:

- Maximum allowable torque: 630 Nm to 31,500 Nm

- Maximum speed: 3500r/min to 1000 r/min

- Shaft hole diameter: ∅35 to ∅200

- Brake disc diameter: ∅355, ∅400, ∅450, ∅500, ∅560, ∅630, ∅710, ∅800, ∅900, ∅1000, ∅1250

- Custom specifications: We can manufacture the coupling based on your provided drawings.

Overview of Elastic Coupling with Brake Disc

The Brake Disc Jaw Elastic Coupling is a reliable power transmission part for cranes, hoists, conveyors, and heavy-duty machinery. It combines torque transmission, vibration damping, and braking in one compact unit. This design improves safety and reduces space compared to traditional systems. Moreover, it ensures stable and efficient performance in demanding industrial conditions.

Structure and Design of Crane Jaw Coupling

This coupling includes two precision-machined hubs with curved jaws, a flexible elastic spider, and an integrated brake disc. The elastic spider, made from polyurethane or rubber, offers high durability, flexibility, and resistance to wear. In addition, its torsional elasticity reduces vibration, noise, and overload impacts while compensating for misalignment.

The integrated brake disc works directly with braking systems, delivering smooth and efficient stopping power. As a result, users eliminate the need for an extra brake wheel, which saves installation space and reduces maintenance costs.

Key Advantages of Brake Disc Elastic Shaft Coupling

-

High torque capacity with compact structure

-

Built-in braking disc for improved safety

-

Elastic damping that absorbs shocks and vibration

-

Compensation for axial, radial, and angular misalignment

-

Durable elastic elements with oil resistance and long life

-

Easy installation and low maintenance requirements

Applications in Cranes and Industrial Machinery

The coupling suits overhead cranes, hoists, metallurgy machinery, mining equipment, and conveyors. These industries often require frequent start-stop cycles and high safety standards. Therefore, the Brake Disc Jaw Elastic Coupling ensures smoother operation, longer machine service life, and reliable braking control.

Customization Options for Industrial Coupling

Customers can choose from various sizes and torque ranges. The brake disc is available in multiple diameters and thicknesses to match braking systems. Furthermore, our engineering team designs each coupling with strict material selection and precision machining.

Quality Assurance and Performance Testing

Before delivery, each coupling undergoes torque tests, dynamic balance checks, and braking efficiency tests. Consequently, the product guarantees stable performance in heavy-duty applications.

Why Choose Our Brake Disc Jaw Elastic Coupling Supplier

As a professional manufacturer, we supply couplings for OEM and ODM projects. Our products meet industry standards and fit a wide range of crane and industrial machinery. In addition, we provide reliable after-sales service, ensuring our couplings remain the preferred choice for crane parts and industrial power transmission systems.

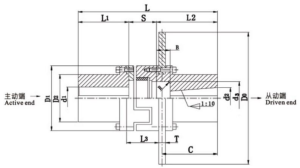

The parameters and dimensions of the MLPK Brake Disc Jaw Elastic Coupling

| Type | Nominal Torque | Braking Torque | Permissible speed | Shaft hole diameter d1, d2 |

Shaft hole length L1 ,L2 |

L | S | L3 | D1 | D2 | B | d3 | R | C | D₀ ×T | Elastomer Model |

Weight | Moment of Inertia |

| N.m | N.m | r/min | mm | mm | mm | mm | kg | kg.m² | ||||||||||

| MLPK6 | 630 | 1800 | 3500 | 35,38 | 85 | 231 | 67 | 71 | 145 | 85 | 22 | 65 | 2 | 70 | 355×20 | MT6-b | 27 | 0.279 |

| 40,42 | 112 | 291 | 100 | 400×20 | 35 | 0.452 | ||||||||||||

| 45,48,55 | 95 | 450×30 | 55 | 0.99 | ||||||||||||||

| MLPK7 | 1120 | 2850 | 3250 | 45,48 | 112 | 291 | 67 | 71 | 170 | 110 | 28 | 80 | 2 | 95 | 400×30 | MT7-b | 54 | 0.66 |

| 50,55 | 450×30 | 62 | 1.02 | |||||||||||||||

| 60,63,65 | 142 | 351 | 125 | 500×30 | 71 | 1.51 | ||||||||||||

| MLPK8 | 1800 | 4950 | 3000 | 50,55 | 112 | 300 | 76 | 81 | 200 | 135 | 28 | 95 | 2.5 | 94 | 400×30 | MT8-b | 76 | 0.80 |

| 60,63 | 142 | 360 | 124 | 450×30 | 84 | 1.16 | ||||||||||||

| 65,70 | 500×30 | 93 | 1.66 | |||||||||||||||

| 71,75 | 560×30 | 150 | 2.48 | |||||||||||||||

| MLPK9 | 2800 | 7740 | 2800 | 60,63 | 142 | 364 | 80 | 86 | 230 | 160 | 35 | 116 | 2.5 | 124 | 500×30 | MT9-b | 116 | 1.78 |

| 65,70,75 | 560×30 | 128 | 2.61 | |||||||||||||||

| 80,85,90,95 | 172 | 424 | 154 | 630×30 | 143 | 3.98 | ||||||||||||

| MLPK10 | 4500 | 11940 | 2600 | 70,75 | 142 | 379 | 95 | 101 | 262 | 180 | 40 | 140 | 2.5 | 124 | 500×30 | MT10-b | 139 | 2.12 |

| 80,85 | 172 | 439 | 154 | 560×30 | 150 | 2.96 | ||||||||||||

| 90,95 | 630×30 | 168 | 4.33 | |||||||||||||||

| 100,110 | 212 | 519 | 194 | 710×30 | 185 | 6.66 | ||||||||||||

| MLPK11 | 7100 | 17550 | 2250 | 80,85 | 172 | 455 | 111 | 117 | 300 | 200 | 40 | 150 | 3 | 154 | 800×30 | MT11-b | 189 | 4.70 |

| 90,95 | 710×30 | 225 | 6.92 | |||||||||||||||

| 100,110,120 | 212 | 535 | 194 | 800×30 | 250 | 10.5 | ||||||||||||

| MLPK12 | 11200 | 29100 | 2000 | 90,95 | 172 | 469 | 124 | 130 | 360 | 225 | 45 | 160 | 3 | 154 | 710×30 | MT12-b | 243 | 8.29 |

| 100,110,120,125 | 212 | 548 | 194 | 800×30 | 311 | 13.55 | ||||||||||||

| 130 | 252 | 628 | 234 | 900×30 | 374 | 20.57 | ||||||||||||

| MLPK13 | 12500 | 40050 | 1800 | 100,110,120,125 | 212 | 548 | 124 | 130 | 400 | 225 | 50 | 160 | 3 | 194 | 900×30 | MT13-b | 390 | 21.38 |

| 130,140 | 252 | 628 | 234 | 1000×30 | 441 | 29.12 | ||||||||||||

| MLPK14 | 20000 | 42000 | 1500 | 110,120,125 | 212 | 548 | 124 | 130 | 460 | 260 | 50 | 180 | 4 | 194 | 1000×30 | MT14-b | 467 | 30.67 |

| 130,140,150 | 252 | 628 | 229 | 1000×40 | 550 | 40.75 | ||||||||||||

| MLPK15 | 25000 | 50000 | 1200 | 120,125 | 212 | 559 | 135 | 141 | 500 | 300 | 60 | 215 | 5 | 194 | 1000×30 | MT15-b | 548.2 | 35.72 |

| 130,140,150 | 252 | 639 | 234 | 1250×30 | 652.2 | 43.03 | ||||||||||||

| 160,170,180 | 302 | 739 | 279 | 1250×30 | 751.6 | 54.17 | ||||||||||||

| MLPK16 | 31500 | 63000 | 1000 | 130,140,150 | 252 | 639 | 135 | 141 | 550 | 340 | 70 | 250 | 5 | 234 | 1000×30 | MT16-b | 598.2 | 38.81 |

| 160,170,180 | 302 | 739 | 284 | 1250×30 | 702.2 | 46.12 | ||||||||||||

| 190,200 | 352 | 839 | 329 | 1250×30 | 801.6 | 57.26 | ||||||||||||