Top 10 Questions About Overhead Crane Parts Answered

Overhead cranes are essential lifting systems used in workshops, steel plants, and industrial facilities. The performance and safety of a crane depend on the quality of its components. In this article, HL CRANE, a professional fabrikant kraanonderdelen in China, answers the 10 most frequently asked questions about overhead crane parts.

1. What Are the Main Parts of an Overhead Crane?

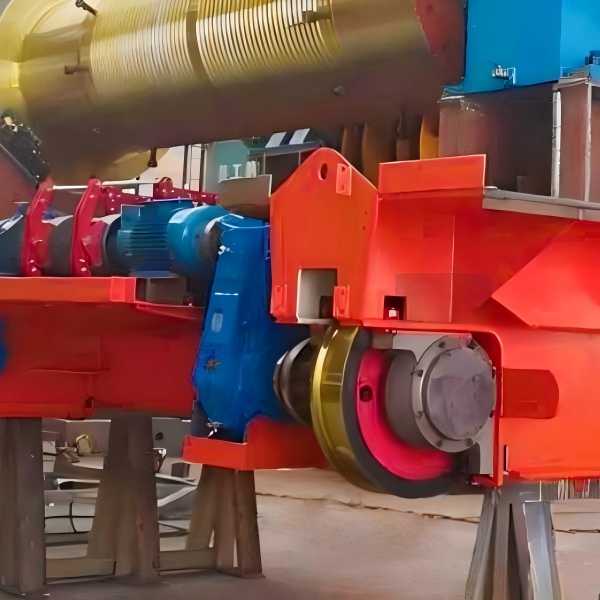

An overhead crane typically includes a bridge, trolley, hoist, end carriages, and an electrical control system. The major mechanical parts are the kraanhaak, wiel, trommel, koppelingen sheave. Each part plays a vital role in ensuring lifting stability and operator safety.

For more product details, visit Overhead Crane Hooks of Kraanwielen.

2. How Do I Choose the Right Crane Hook?

The crane hook is one of the most critical safety components. Select your hook based on load capacity, working class (A1–A8), and application environment. For foundries or heavy-duty cranes, forged steel hooks with an A7 or A8 rating are recommended. Make sure your hook meets recognized standards such as DIN 15401/15402 or GOST 6627-74.

3. What Is the Function of a Crane Wheel?

Crane wheels bear the entire crane weight and allow smooth movement along rails. They are typically made from 42CrMo or 65Mn alloy steel with precision heat treatment. Regular inspection and lubrication prevent track damage and ensure reliable operation.

4. What Type of Drum Is Used in Overhead Cranes?

De kraantrommel winds and unwinds the wire rope, converting rotational motion into vertical lifting. High-quality drums are made from seamless or cast steel with precision-machined grooves. Matching the correct rope diameter prevents uneven wear and extends equipment lifespan.

5. What Does a Crane Coupling Do?

De kraankoppeling connects the motor to the gearbox or drum shaft and transfers torque efficiently. Common types include gear couplings, elastic couplings, and pin couplings. Selecting the right type minimizes vibration and improves transmission stability.

6. Why Are Sheaves and Pulleys Important?

Sheaves (pulleys) guide the wire rope, allowing smoother and safer lifting operations. They must have proper groove dimensions and surface hardness. Using sealed bearings and high-strength materials reduces maintenance and increases service life.

7. How Often Should Overhead Crane Parts Be Inspected?

Inspection frequency depends on your crane’s duty class. For heavy-duty cranes, daily visual checks and monthly detailed inspections are recommended. Look for cracks, wear, and deformation on hooks, wheels, and drums. Keeping detailed maintenance records ensures compliance with safety regulations.

8. Can I Replace Crane Parts with Non-Original Components?

While non-original components may appear cost-effective, they often lack proper tolerances and certified material quality. HL CRANE strongly recommends using OEM or original-quality parts to maintain compatibility, performance, and safety.

9. What Causes Premature Wear in Crane Parts?

The most common causes are overloading, poor lubrication, misalignment, and incorrect rope installation. Following a regular maintenance schedule and using suitable lubricants can significantly extend component lifespan.

10. Where Can I Buy Reliable Overhead Crane Parts?

You can purchase high-quality, certified crane components directly from HL CRANE. We supply hooks, wheels, drums, couplings, and complete crane assemblies. All products comply with ISO, FEM, and GOST standards and can be customized to match your lifting requirements. For consultation, please contact met ons opnemen.

Conclusie

Understanding overhead crane parts helps you improve operational safety and efficiency. Whether you are replacing worn components or assembling a new system, always choose durable, certified, and precisely engineered parts.

HL CRANE provides OEM and ODM services for all crane components, delivering reliable quality and competitive pricing to global customers. Visit HL CRANE’s official website for more technical information and customized solutions.

FAQs About Overhead Crane Parts

1. What is the lifespan of overhead crane parts?

With proper maintenance, key components like hooks and wheels can last 5–10 years depending on usage and environment.

2. Can I get custom-designed crane components?

Yes, HL CRANE offers OEM and custom manufacturing based on your drawings or samples.

3. How do I identify if a crane hook is damaged?

Check for cracks, bending, or increased throat opening. Replace immediately if any deformation is detected.

4. Are HL CRANE parts compatible with European and Russian cranes?

Yes. Our parts meet DIN, FEM, and GOST standards, ensuring compatibility with most global crane systems.

5. What material is best for crane wheels?

Medium-carbon alloy steel, such as 40Cr, is ideal for its high hardness and wear resistance after heat treatment.

6. Do you supply spare parts for foundry cranes?

Yes. HL CRANE provides heavy-duty A7–A8 class crane parts specially designed for foundries, steel mills, and industrial workshops.