Maintenance Guide: How to Extend the Life of Crane Wheels

Crane wheels are among the most critical components in any overhead crane system. They bear the load, ensure smooth motion along the rails, and directly affect operational efficiency and safety. Poor maintenance can lead to wheel wear, misalignment, and even costly equipment downtime. In this guide, HL CRANE — a trusted OEM overhead crane parts manufacturer in China — shares professional insights on how to properly maintain your crane wheels and maximize their service life.

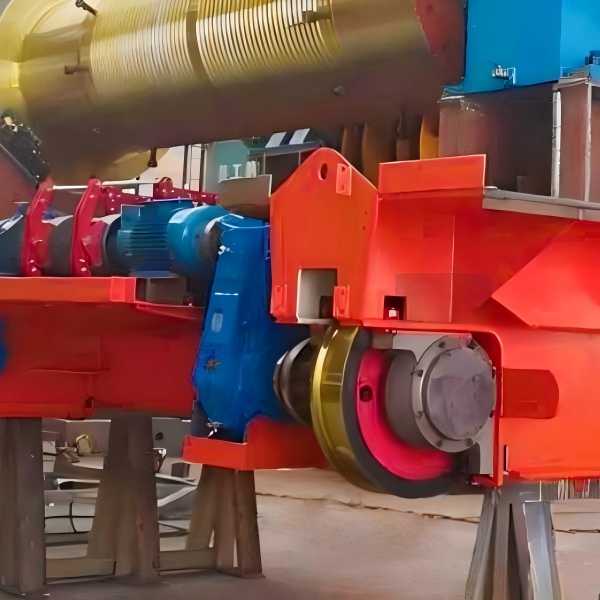

1. Understand the Role of Crane Wheels

Crane wheels support the full weight of the crane and its load, transmitting motion along rails through continuous rolling and friction. Over time, contact stress and misalignment can cause surface fatigue, cracks, or even flange breakage. Using high-quality forged wheels from a reliable supplier like HL CRANE ensures excellent hardness, wear resistance, and longer durability.

2. Regular Inspection and Lubrication

Routine inspections are the foundation of effective crane wheel maintenance. You should:

-

Inspect weekly for cracks, uneven wear, or pitting on the tread and flange.

-

Check alignment between the wheel and the rail — even small deviations can lead to accelerated wear.

-

Lubricate the bearings regularly to reduce friction and prevent overheating.

-

Clean the wheel surface to remove dust, oil, or metal chips that could affect smooth rolling.

Proper lubrication not only minimizes wear but also reduces the risk of wheel seizing during operation.

3. Monitor Rail Conditions

Even the best wheel can wear out quickly if the rail is damaged or misaligned. Check for:

-

Rail straightness and parallelism.

-

Loose fasteners or uneven joints.

-

Surface corrosion or debris buildup.

A good practice is to conduct a full track alignment check every six months. Remember, maintaining both the wheel and rail in optimal condition helps reduce side forces and vibration.

4. Replace Worn Wheels Timely

Crane wheel wear is inevitable, but timely replacement can prevent larger mechanical issues. Signs that your wheel needs replacement include:

-

Flange thickness reduced beyond standard limits.

-

Excessive flat spots or spalling.

-

Visible cracks or deformation.

When replacing, always use OEM-specification wheels. At HL CRANE, all wheels are precision-machined and heat-treated to ensure dimensional accuracy and consistent hardness, compatible with both single and double-girder cranes.

5. Ensure Proper Wheel Alignment

Misaligned crane wheels cause side thrust and uneven pressure, which can lead to rail and bearing damage. Use laser alignment tools or professional gauges to:

-

Check wheel-to-rail clearance.

-

Adjust end carriage alignment.

-

Verify equal wheel load distribution.

HL CRANE’s engineering team provides alignment consultation and customized end carriage designs to help you achieve optimal balance and longer service life.

6. Choose Quality Materials and Heat Treatment

Wheel quality starts from the material. HL CRANE uses high-strength forged steel (such as 40Cr, 65Mn, or ZG430-640) and applies advanced heat-treatment technology for optimal surface hardness (HB320–HB380). This ensures that wheels resist fatigue and deformation under heavy-duty, continuous operation — ideal for foundries, steel mills, and industrial workshops.

7. Partner with a Reliable OEM Supplier

Selecting the right crane parts manufacturer is key to long-term performance. As an experienced OEM overhead crane parts supplier, HL CRANE offers:

-

Custom-made wheels, hooks, pulleys, couplings, and drums.

-

Advanced machining and testing equipment.

-

Strict quality control for international standards.

-

Fast delivery and technical support for global clients.

Working with HL CRANE means you get both quality assurance and engineering expertise that protect your investment.

Conclusion

Crane wheel maintenance isn’t just a routine task — it’s an investment in operational safety and longevity. By performing regular inspections, ensuring proper lubrication, monitoring rail conditions, and choosing reliable OEM components, you can significantly extend the life of your crane wheels.

HL CRANE continues to serve customers worldwide with precision-engineered crane components designed for durability, performance, and efficiency.

Visit www.hnhlcrane.com to learn more about OEM crane wheels, end carriages, and other lifting equipment solutions.

Frequently Asked Questions (FAQ)

1. How often should I inspect my crane wheels?

It is recommended to perform a visual inspection every week and a detailed inspection every three months. Check for surface cracks, uneven wear, and flange deformation. Early detection of wear can prevent costly downtime and accidents.

2. What causes premature wear on crane wheels?

Premature wear is usually caused by rail misalignment, uneven load distribution, or insufficient lubrication. Using poor-quality materials or operating cranes under overload conditions can also accelerate wheel damage. Regular alignment and maintenance are key to preventing this.

3. What material does HL CRANE use for manufacturing crane wheels?

HL CRANE uses forged steel such as 40Cr, 65Mn, and ZG430-640, combined with advanced heat treatment for optimal hardness and wear resistance. This ensures that every wheel maintains strength, precision, and long service life even under heavy-duty operation.

4. Can I replace only one crane wheel, or should I replace them in pairs?

It is recommended to replace crane wheels in pairs to maintain balance and ensure smooth operation. Replacing only one wheel may lead to uneven load distribution and faster wear on the remaining wheels.

5. Why choose HL CRANE as your OEM crane wheel supplier?

HL CRANE is a professional OEM manufacturer of overhead crane parts in China with years of export experience. The company provides:

-

High-quality forged crane wheels and assemblies

-

Strict quality control under ISO standards

-

Custom design and technical support

-

Fast global delivery