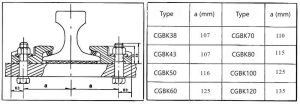

CGBK Κλιπ ράγας

Specifications of CGBK Rail Clips

- Models: CGBK38, CGBK43, CGBK50, CGBK60, CGBK70, CGBK80, CGBK100, CGBK120

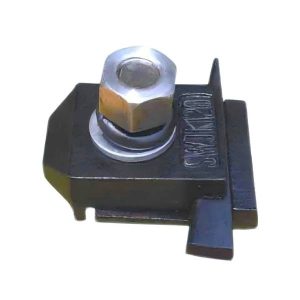

- Fixing Method: Bolt fixing

Features of CGBK Rail Clips

- Ευκολία εγκατάστασης και συντήρησης

CGBK Rail Clips are designed to facilitate rail installation, adjustment, and replacement, ensuring efficiency in operations. - Noise Reduction and Vibration Dampening

Thanks to the rubber tongue and composite rubber pad, the clips provide cushioning and effectively reduce noise. - Bolt Torque Specifications

The M22 bolts used in the system are tightened with a torque of 170 N·m. - Maximum Lateral Force

The clips can withstand a maximum lateral force of 80 kN, ensuring stability under heavy loads.

Key Considerations for Selecting CGBK Rail Clips

- Compatibility with Crane Wheels and Rails

- The crane’s horizontal wheels must match the specifications of the chosen rail type.

- Clearance Between Crane Wheels and Rail Clips

- Ensure a clearance of less than 10 mm between the crane’s horizontal wheels and the rail clips.

- If this condition is not met, reverse bolt installation can be used to minimize space occupied by the rail clips.

- Reinforcement for Heavy-Duty Cranes

- For cranes operating under extra-heavy-duty conditions, replace the composite rubber pad under the rail with a 6 mm thick steel plate (material: Q235).

- Model Selection Based on Rail Type

- Choose the appropriate CGBK clip model according to the rail type. For instance, for rail type QU100, use the CGBK100 model.

Installation Steps for CGBK Rail Clips

- Preparation of Crane Beams

- Drill holes in the crane beams according to the specified AA value and maintain a 500 mm spacing between clip groups.

- Laying the Rubber Pad

- Lay the composite rubber pad continuously along the length of the rail.

- Positioning the Clips

- Place the front section of the CGBK Rail Clip against the rail and insert the bolts.

- Tightening the Bolts

- Tighten the bolts securely, ensuring the rubber tongue presses tightly against the rail.