Overhead Crane Wire Rope Drum Replacement: What You Need to Know

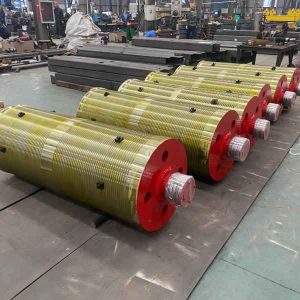

When it comes to maintaining an overhead crane, one of the most critical components to monitor is the wire rope drum. This essential part ensures the safe and efficient lifting of heavy loads. Over time, due to constant use and pressure, the drum may wear out, and a replacement wire rope drum for overhead crane becomes necessary.

In this guide, we’ll walk you through everything you need to know about overhead crane wire rope drums replacement, including signs of wear, replacement options, and how to choose the right drum for your system.

🔧 Common Signs You Need a Replacement Wire Rope Drum

A grooved wire rope drum for 10 ton crane or similar model typically operates under high loads daily. Look out for:

-

Excessive groove wear or deformation

-

Cracks or fatigue in the forged steel wire rope drums

-

Slipping or misalignment of the rope

-

Noisy or unstable hoisting movements

If any of these symptoms appear, it’s time to consider a crane wire rope drums with grooves replacement.

⚙️ Choosing the Right Crane Rope Drum

When replacing a wire rope drum, it’s vital to select the correct specifications. Consider the following:

1. Crane Type

-

Single-girder or double girder overhead crane

-

Electric hoist crane or winch-driven systems

2. Load Capacity

-

Ensure your new drum fits the lifting weight, such as a 10-ton crane or heavy duty crane rope drum assembly

3. Material

-

Opt for forged steel wire rope drums for durability

-

Use precision machined wire rope drums for high-accuracy operations

4. Customization

-

If using a unique setup, you may need a custom crane drum for electric hoist, including features like a shaft and bearings or special grooves.

🛠️ Installing the Replacement Drum

Replacing a wire rope drums with shaft and bearings for bridge crane requires professional expertise. Make sure to:

-

Use proper lifting tools

-

Align the drum correctly with the gearbox

-

Lubricate all moving parts

-

Test run under supervision

Incorrect installation may damage the crane or pose safety risks.

✅ Maintenance Tips After Replacement

After installing a new grooved drum for lifting crane application, regular maintenance is essential:

-

Check grooves and alignment monthly

-

Keep wire rope tension balanced

-

Use proper wire rope diameter

-

Ensure the winch and hoisting system is synchronized

📌 Final Thoughts

Whether you’re replacing a steel grooved drums or upgrading to a custom crane wire rope drums, choosing the right part is critical for your overhead crane’s performance and safety. If you’re unsure, consult a manufacturer who can offer tailored wire rope drum assembly solutions based on your crane model.

Need help finding the right drum for your crane? Contact us now for custom crane drums with shaft and bearings built to your exact specifications!