Crane Parts Solutions for Steel Mills: Heat, Dust, and Heavy Loads

Steel mills operate in some of the harshest industrial environments in the world. High temperatures, heavy dust, continuous production cycles, and extremely heavy loads place enormous pressure on overhead cranes and their components. Choosing the right crane parts is essential to ensure safety, productivity, and long-term reliability.

At HL CRANE, we specialize in providing professional crane parts solutions for steel plants, helping customers reduce downtime and improve operational efficiency.

Challenges in Steel Mill Crane Operations

Compared with general factories, steel mills present unique challenges for crane systems:

1. High Temperature

Molten metal, hot slabs, and furnaces create extreme heat conditions. Standard components may fail quickly without proper heat-resistant design.

2. Heavy Dust and Debris

Steel production generates large amounts of metal dust, scale, and particles. These contaminants can damage bearings, motors, and electrical systems.

3. Heavy and Continuous Loads

Steel coils, billets, and ladles often weigh dozens of tons. Cranes must operate continuously under high stress, requiring strong mechanical structures.

Key Crane Parts for Steel Mill Applications

To overcome these challenges, steel mills need specially designed crane components.

Hoisting Mechanism

The hoist system must feature high-strength wire ropes, hardened drums, and reliable brakes. Heat-resistant materials and reinforced structures are essential.

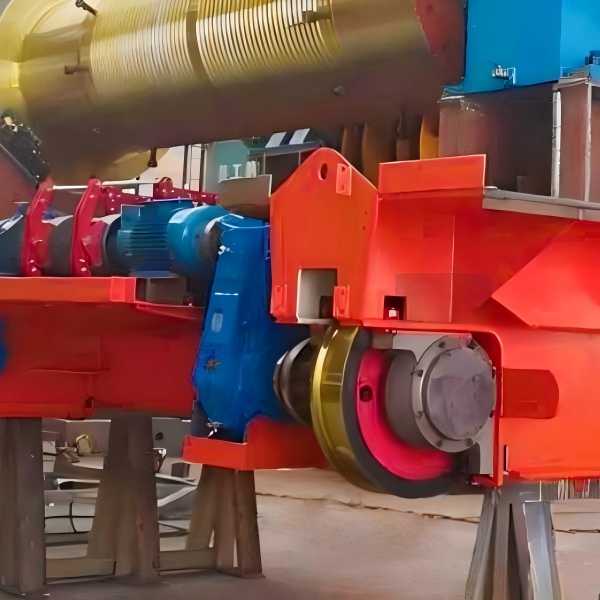

Crane Wheels and Wheel Blocks

Crane wheels in steel mills are exposed to high loads and rail deformation. HL CRANE supplies hardened alloy steel wheels with excellent wear resistance.

Learn more about our crane wheel solutions here:

👉 https://www.hnhlcrane.com/products/crane-wheel/

Motors and Gearboxes

Motors and gearboxes should be heavy-duty, with IP55 or higher protection levels. Variable frequency drive (VFD) systems help improve smooth operation and reduce mechanical impact.

Electrical System

Electrical components must be dustproof, heat-resistant, and stable under voltage fluctuations. Proper cable protection and sealed control cabinets are crucial.

Why Choose HL CRANE for Steel Mill Crane Parts?

With years of experience in the crane industry, HL CRANE understands the real working conditions of steel plants.

Our advantages include:

-

✔ Customized solutions for high-temperature environments

-

✔ Strict quality control and testing

-

✔ Stable supply and fast delivery

-

✔ Professional technical support

-

✔ Competitive pricing from China manufacturers

We provide complete spare parts, including drums, hooks, couplings, brakes, motors, gearboxes, and end carriages.

You can explore our full product range at:

👉 https://www.hnhlcrane.com

Maintenance Tips for Steel Mill Cranes

Even the best components require proper maintenance. We recommend:

-

Regular lubrication and cleaning

-

Periodic inspection of wire ropes and brakes

-

Monitoring gearbox oil condition

-

Checking electrical insulation

-

Replacing worn parts in time

For general crane safety standards, you may refer to guidelines from organizations such as OSHA:

👉 https://www.osha.gov/laws-regs

Conclusion

Steel mills demand reliable, durable, and high-performance crane systems. Investing in professional crane parts designed for heat, dust, and heavy loads is the key to stable production and long-term cost savings.

As a trusted supplier, HL CRANE is committed to delivering high-quality crane parts solutions for steel plants worldwide. Whether you need replacement components or complete system upgrades, we are ready to support your projects with reliable products and expert service.

Contact HL CRANE today to optimize your steel mill crane operations and improve productivity.

FAQ

Q1: What types of crane parts are most critical in steel mills?

A: The most critical crane parts in steel mills include hoisting mechanisms, crane wheels, motors, gearboxes, brakes, wire ropes, and electrical systems. These components must be designed to withstand high temperatures, heavy dust, and continuous heavy loads.

Q2: Can HL CRANE provide customized crane parts for high-temperature environments?

A: Yes. HL CRANE offers customized crane parts with heat-resistant materials, reinforced structures, and special surface treatments to ensure stable performance in high-temperature steel mill environments.

Q3: How often should crane parts be inspected in steel plants?

A: In steel mills, crane parts should be inspected daily for basic operation, weekly for key components, and thoroughly checked every 3 to 6 months. Regular inspections help prevent unexpected failures and reduce downtime.

Q4: Are HL CRANE spare parts compatible with international crane brands?

A: Yes. HL CRANE supplies high-quality replacement parts compatible with many international brands such as Demag, Konecranes, and ABUS. Our technical team ensures accurate matching based on drawings and nameplate information.

Q5: What information is needed to order crane spare parts from HL CRANE?

A: To provide accurate quotations, customers should share equipment models, nameplate photos, technical drawings, working conditions, and required quantities. This helps HL CRANE recommend the most suitable and cost-effective solutions.