Best Practices for Overhead Crane Hook Safety and Inspection

In lifting operations, the кука за мостови кран serves as the critical link between the crane and the load. A small defect in this part can lead to serious accidents or costly downtime. To maintain safety and ensure reliable operation, crane hooks must be properly inspected, maintained, and replaced when necessary.

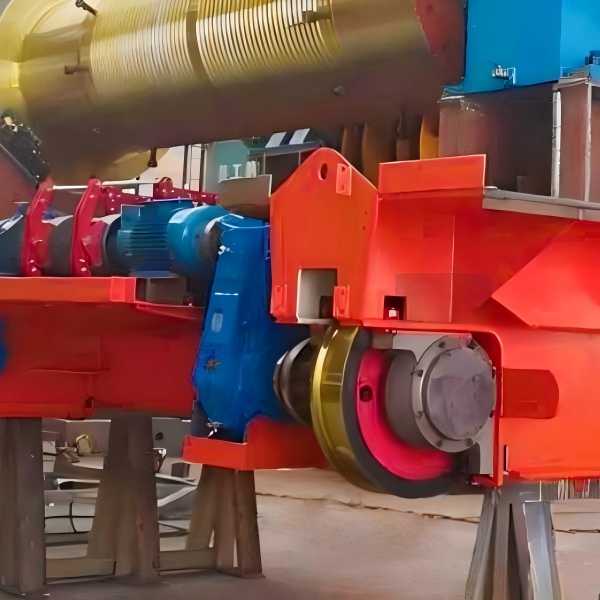

As a professional OEM доставчик на части за мостови кран, HL CRANE provides durable forged hooks, wheels, couplings, and drums designed to meet global industrial standards. This guide outlines the best practices for crane hook safety and inspection, helping you extend equipment lifespan and prevent failures.

1. Understand the Function and Failure Risks

Crane hooks are exposed to heavy tensile and bending forces during lifting. Over time, overloading, improper operation, or material fatigue can cause:

-

Hook deformation or elongation

-

Surface cracks around the neck or saddle

-

Safety latch failure

-

Corrosion or wear

Choosing high-quality forged hooks from HL CRANE’s Crane Hook Series ensures better resistance to these stresses. Each hook is forged from DG20Mn steel, heat-treated for superior strength and toughness.

2. Conduct Daily Visual Inspections

Before every operation, operators should perform a visual inspection of the crane hook. Check for:

-

Cracks, dents, or surface wear

-

Any permanent bending or twisting

-

Missing or damaged safety latches

-

Corrosion and rust

If any of these issues are found, the hook must be taken out of service immediately. Proper maintenance also applies to other load-bearing components like колела за кран and couplings.

3. Schedule Periodic Detailed Examinations

In addition to daily checks, a comprehensive inspection should be performed at least every three months, or after any overload event. Use magnetic particle testing (MT) или dye penetrant testing (PT) to detect hidden cracks.

Measure the throat opening — if it has expanded by more than 5%, the hook must be replaced. Similarly, if wear at the critical points (such as the saddle or eye section) exceeds 10% of the original dimension, it’s no longer safe.

Using OEM replacement parts from HL CRANE’s OEM Crane Parts Supplier page guarantees dimensional precision and compliance with safety standards.

4. Prevent Overloading and Shock Lifting

Overloading is one of the leading causes of hook failure. Operators should always:

-

Avoid exceeding the Safe Working Load (SWL).

-

Prevent shock lifting or sudden jerks during load handling.

-

Regularly calibrate load indicators and limit switches.

According to OSHA Overhead Crane Safety Guidelines, exceeding rated capacity even briefly can drastically shorten the service life of crane components.

5. Replace Hooks with OEM-Certified Parts

When inspection reveals cracks, deformation, or excessive wear, replace the hook immediately with OEM-certified components. HL CRANE manufactures hooks under ISO and FEM standards, ensuring excellent toughness, precise machining, and durability.

By choosing genuine HL CRANE OEM Parts, you ensure:

-

Consistent material quality

-

Compatibility with your crane type

-

Long-term operational safety

6. Keep Maintenance Records

Always maintain a detailed log of inspections, findings, and replacements. This helps ensure traceability and compliance during safety audits. Record:

-

Date and inspector name

-

Measurement data and test results

-

Actions taken (cleaning, repair, or replacement)

A disciplined record system ensures your overhead crane hook maintenance aligns with global safety standards.

7. Operator Training and Awareness

Even the best hooks can fail without proper handling. Operators and maintenance teams should be trained to:

-

Recognize early signs of fatigue

-

Understand load limits and lifting procedures

-

Follow manufacturer recommendations

HL CRANE offers technical support и customized OEM solutions for global clients to improve both safety and efficiency in crane operations.

Посетете www.hnhlcrane.com to explore our full range of products and professional crane part solutions.

❓ Често задавани въпроси (ЧЗВ)

1. How often should crane hooks be inspected?

A visual inspection should be done daily, и comprehensive inspection every three months or after any overload event.

2. What is the maximum allowed deformation for crane hooks?

If the throat opening increases by more than 5% or there’s visible bending, replace the hook immediately to avoid failure.

3. Can cracked crane hooks be repaired?

No. Welding or grinding a cracked hook can alter its heat treatment and reduce its strength. Replacement is the only safe option.

4. What materials are used in HL CRANE’s forged hooks?

HL CRANE използва 42CrMo, 35CrMo, and 20MnSi alloy steel, heat-treated and tested for superior load-bearing performance.

5. Does HL CRANE offer custom hook designs?

Yes. HL CRANE provides custom OEM crane hooks based on customer drawings, lifting class (A3–A8), and operational needs.

Visit the Доставчик на части за кранове OEM page for details.