How to Evaluate a Reliable Overseas Crane Parts Supplier: Complete Buyer’s Guide

In today’s global supply chain, purchasing crane spare parts from overseas manufacturers has become common practice for steel plants, foundries, ports, and equipment service companies. However, the challenge is not finding a supplier, but identifying a reliable overseas crane parts supplier who can deliver consistent quality, safe components, and on-time shipments.

This guide provides practical criteria buyers should use to evaluate suppliers and reduce sourcing risks.

1. Verify Manufacturing Capabilities and Product Scope

The first step is to evaluate whether the supplier actually manufactures crane parts or simply trades them. Real manufacturers offer better control over:

-

Quality

-

Pricing

-

Lead time

-

Engineering customization

Look for a supplier that provides a complete product range, such as hooks, wheels, drums, sheaves, couplings, and end carriages. This indicates vertical capability, not just reselling.

HL CRANE manufactures and supplies OEM-grade crane components for industrial applications.

2. Confirm Compliance With International Standards

Crane parts are safety-critical. Failure can cause major downtime, property damage, or injuries. A reliable supplier should follow key standards such as:

-

FEM

-

ISO

-

GB

-

EN

-

CMAA

Request evidence of material certificates, heat treatment reports, inspection sheets, and load test records.

For reference, see FEM standards for cranes published by the European Materials Handling Federation.

3. Evaluate Quality Control and Inspection Procedures

A dependable supplier should implement structured QC processes, including:

-

Chemical composition analysis

-

Non-destructive testing (NDT)

-

Hardness testing

-

Load testing

-

Dimensional inspection

Ask suppliers to share photographs or videos of their QC procedures to verify real manufacturing activity.

4. Assess Lead Time, Logistics, and Reliability

International buyers often underestimate the impact of lead times. A professional supplier should provide:

-

Realistic production schedules

-

Export experience

-

Strong packing standards

-

Shipping documentation

Unreliable suppliers often promise unrealistic delivery times to win orders and then delay.

5. Compare Pricing Based on Value, Not Just Unit Cost

The lowest price often results in:

-

Poor material quality

-

Shorter lifespan

-

Inconsistent performance

-

Higher downtime costs

The total cost of ownership should be considered, especially for high-load parts like wheels and hooks.

A reliable supplier provides transparent pricing and guarantees replacement support.

6. Evaluate Customer Support and Technical Capability

Strong customer support is essential for industrial buyers. Look for suppliers who offer:

-

Professional technical guidance

-

Engineering drawings

-

Customization

-

Fast response

Suppliers who only respond “yes/no” often lack technical depth.

7. Analyze Online Presence and Industry Reputation

A reliable supplier should have:

-

Website with detailed product information

-

Case studies

-

Certifications

-

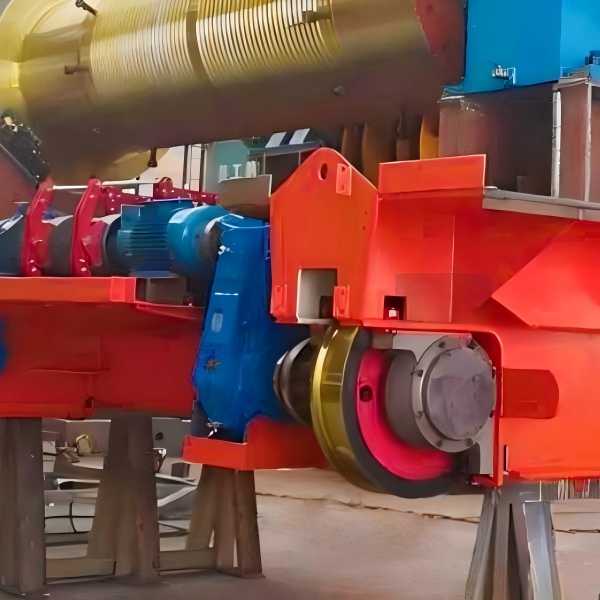

Real factory images

Visit the manufacturer’s website to evaluate expertise.

For example: HL CRANE is a professional supplier of overhead crane parts based in China:

https://www.hnhlcrane.com

Conclusion

Choosing a reliable overseas crane parts supplier requires a professional evaluation process. Buyers should assess manufacturing capability, standards compliance, QC systems, technical support, and lead-time reliability. A professional supplier like HL CRANE can reduce downtime, improve safety, and support long-term operations.

FAQ 1: What certifications should an overseas crane parts supplier provide?

A reliable supplier should provide material certificates, heat treatment reports, load test data, and compliance documents related to FEM, ISO, EN, or GB standards. These certifications help verify safety, durability, and traceability of crane components, especially when used in heavy-duty applications.

FAQ 2: What factors affect the price of crane parts from overseas suppliers?

Price differences are typically influenced by material grade, heat treatment, load capacity, precision, surface treatment, and production scale. Extremely low prices may indicate inferior materials or poor QC, leading to long-term costs such as downtime, repair, or safety risks.

FAQ 3: What is the best way to reduce risk when working with a new overseas supplier?

Start with a small pilot order to test product quality, lead time, and communication. Evaluate packaging quality, documentation accuracy, and after-sales support. A trustworthy supplier should be willing to support testing before large-scale procurement.

FAQ 4: How important is technical support when sourcing crane parts internationally?

Technical support is essential because buyers often require compatibility verification, customization, or engineering recommendations. Suppliers with strong technical expertise can help avoid compatibility issues, reduce installation time, and improve overall performance and safety of the crane system.