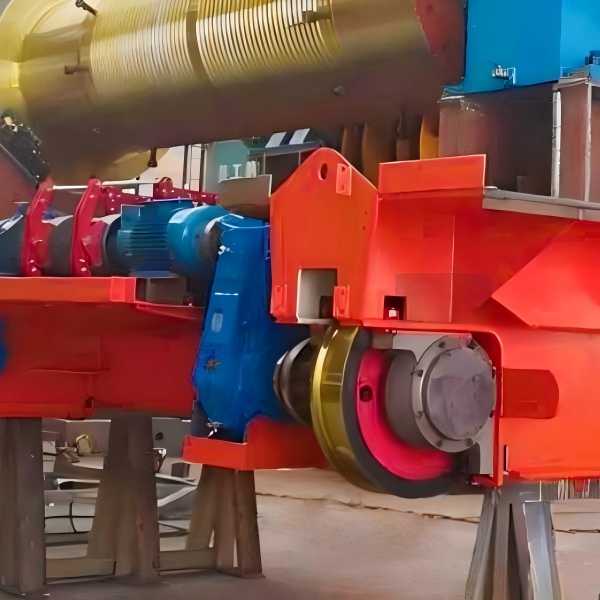

Angle bearing box crane wheel

Angle Bearing Box Crane Wheel Parameters:

- Specifications: Φ250, Φ350, Φ400, Φ500, Φ600, Φ700, Φ800

- Wheel Material: ZG430-640, 45 steel, 50SiMn, 65Mn, 42CrMo

- Wheel Type: Double flange, Single flange, No flange

- Wheel Groove Width: Determined according to track model

- Custom Orders: We can manufacture based on your drawings and dimensions provided.

The Angle Bearing Box Crane Wheel serves as an important mechanical component that supports lifting machinery and its loads, while enabling the crane to travel back and forth along the track. The design and manufacturing processes of this wheel set take into account multiple factors to ensure its performance and safety.

Wheel Set Applications:

The crane wheel set primarily serves on single and double girder cranes.

Depending on the crane’s tonnage and operating environment, the crane wheel set can be classified into the following types:

- For cranes with a tonnage under 50 tons: The main girder wheels feature a double-flange structure, equipped with seven-class tapered bearings. The bearing box utilizes an angular design, and each wheel set includes four bearings. The wheel tread is typically made of cast iron. For the trolley wheels, a single-flange structure is commonly used, with an angular bearing box and two seven-class bearings per wheel set. The wheels are made of cast copper.

- For large-tonnage cranes (50 tons and above): The main girder wheels typically use heavy-duty wheel sets with double-flange structure wheel treads. The bearing box can be either angular or circular in shape, usually made of cast copper. The bearings are of the third-class variety, and the wheels are made of either cast or forged material. For the trolley wheel set, a double-flange structure is also employed, with third-class bearings, and the bearing box is made of cast steel.

The design and manufacturing standards for the Angle Bearing Box Crane Wheel ensure the safe and stable operation of the lifting machinery, while also considering ease of maintenance and cost-effectiveness. This wheel set finds wide applications in various industrial and construction environments and is an essential component of lifting machinery.

Surface Wear Resistance of the Wheel Set:

The wear resistance of the wheel set’s surface plays a crucial role, as it directly influences its service life. Consequently, high-quality wheel sets undergo heat treatment on the tread. When the surface hardness reaches HB300-350, the service life of the wheel set increases significantly, making it a qualified wheel set.

Technical Parameters:

The technical parameters of the wheel set are crucial, as the alignment and level of the operating mechanism during use directly affect its performance. If the alignment is too far off, it can result in track wear, increased resistance, vibration, and significant noise pollution.

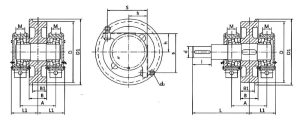

Single-Rim Wheelset

| Wheel diameter | Drawing No. | Size (mm) | ||||||||||||

| D | D1 | B | B1 | A | L | L1 | h | S | M | d | I | d1 | ||

| Φ250 | L754 | 250 | 280 | 90 | 70 | 180 | 237 | 130 | 80 | 180 | 30 | 45 | 82 | M20 |

| L755 | 250 | 280 | 90 | 70 | 180 | / | 130 | 80 | 180 | 30 | / | / | ||

| φ315 | L774 | 315 | 345 | 100 | 81 | 200 | 320 | 150 | 105 | 225 | 50 | 65 | 105 | |

| L775 | 315 | 345 | 100 | 81 | 200 | / | 150 | 105 | 225 | 50 | / | / | ||

| Φ350 | L756 | 350 | 380 | 100 | 81 | 200 | 320 | 150 | 105 | 225 | 50 | 65 | 105 | |

| L757 | 350 | 380 | 100 | 81 | 200 | / | 150 | 150 | 225 | 50 | / | / | ||

| φ400 | L758 | 400 | 440 | 120 | 100 | 240 | 365 | 170 | 120 | 260 | 50 | 80 | 130 | |

| L759 | .400 | 440 | 120 | 100 | 240 | / | 170 | 120 | 260 | 50 | / | / | ||

| Φ500 | L762 | 500 | 540 | 130 | 110 | 270 | 365 | 195 | 140 | 300 | 50 | 80 | 130 | |

| L763 | 500 | 540 | 130 | 110 | 270 | / | 195 | 140 | 300 | 50 | / | / | ||

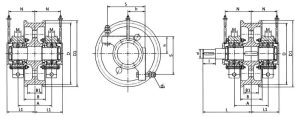

Double-Rim Wheelset

| Wheel diameter | Drawing No. | Size (mm) | ||||||||||||

| D | D1 | A | B | B1 | L | L1 | h | S | M | d | I | d1 | ||

| φ500 | L764 | 500 | 540 | 280 | 210/160 | 150/100 | 400 | 230 | 140 | 310 | 50 | 75 | 105 | M24 |

| L765 | 500 | 540 | 280 | / | 230 | 140 | 310 | 50 | / | / | ||||

| Φ600 | L766 | 600 | 640 | 280 | 210/160 | 150/100 | 415 | 230 | 140 | 310 | 50 | 85 | 130 | |

| L767 | 600 | 640 | 280 | / | 230 | 140 | 310 | 50 | / | / | ||||

| φ700 | L768 | 700 | 750 | 315 | 210/160 | 150/100 | 455 | 260 | 160 | 350 | 80 | 90 | 130 | M30 |

| L769 | 700 | 750 | 315 | / | 260 | 160 | 350 | 80 | / | / | ||||

| φ700 | L770 | 800 | 850 | 365 | 210/160 | 150/100 | 500 | 300 | 190 | 410 | 90 | 95 | 130 | |

| L771 | 800 | 850 | 365 | / | 300 | 190 | 410 | 90 | / | / | ||||

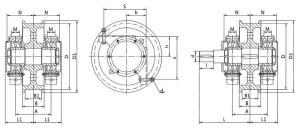

Heavy-Duty Wheelset

| Wheel diameter | Drawing No. | Size (mm) | ||||||||||||

| D | D1 | B | B1 | A | L | L1 | h | S | M | d | I | d1 | ||

| Φ600 | L174B | 600 | 650 | 210/160 | 150/100 | 325

325 |

470 | 255 | 180 | 390 | 70 | 95 | 130 | M24 |

| L175B | 600 | 650 | / | 255 | 180 | 390 | 70 | / | / | |||||

| φ700 | L176B | 700 | 750 | 210/160 | 150/100 | 360

360 |

500 | 280 | 200 | 440 | 80 | 110 | 165 | M30 |

| L177B | 700 | 750 | / | 280 | 200 | 440 | 80 | / | / | |||||

| Φ700 | L178B | 700 | 750 | 210/160 | 150/100 | 380

380 |

500 | 305 | 220 | 485 | 80 | 110 | 165 | |

| L179B | 700 | 750 | / | 305 | 220 | 485 | 80 | / | / | |||||

| φ800 | L196B | 800 | 850 | 210/160 | 150/100 | 380

380 |

500 | 305 | 220 | 485 | 80 | 110 | 165 | |

| L197B | 800 | 850 | / | 305 | 220 | 485 | 80 | / | / | |||||

Video

Faq

Q1: What are crane wheels and why are they important?

A1: Crane wheels are essential components that support and guide the movement of cranes on rails. High-quality wheels reduce wear, extend equipment lifespan, and ensure smooth operation. HLCRANE provides precision-engineered wheels designed for heavy-duty performance in demanding environments.

Q2: What materials are used for manufacturing crane wheels?

A2: HLCRANE crane wheels are made from durable steel plate with optimized heat treatment. This process improves hardness, wear resistance, and load-bearing capacity, making them suitable for continuous operation in steel mills, ports, and construction sites. More product details can be found on www.hnhlcrane.com.

Q3: Can crane wheels be customized?

A3: Yes. HLCRANE offers complete customization, including wheel diameter, tread width, bore size, surface hardness, and mounting type. Our engineering team can design solutions based on your crane model, rail conditions, and working environment. For inquiries, please visit www.hnhlcrane.com.

Q4: How do I choose the right crane wheel for my crane?

A4: Selecting the correct crane wheel depends on factors such as load capacity, rail size, wheel material, and working conditions. HLCRANE provides technical support and recommendations to help you select the best wheel for your equipment.

Q5: What types of cranes use these wheels?

A5: Crane wheels are widely used in overhead cranes, gantry cranes, port cranes, and metallurgical cranes. HLCRANE products are trusted in industries such as steel production, foundries, mining, logistics, and heavy construction. More application cases are available at www.hnhlcrane.com.

Q6: How does HLCRANE ensure quality and reliability?

A6: HLCRANE uses advanced production equipment, strict heat treatment processes, and full inspection systems to guarantee durability and precision. Each crane wheel is tested for hardness, strength, and surface finish before delivery to ensure reliable performance.